Alkali Resistant Fiberglass Roving Assembled 3200 Tex

Video

Khoom Paub meej

Khoom npe |

Alkali Resistant Fiberglass Roving Assembled 3200 Tex |

MOQ |

≥1000 kg |

Daim ntawv thov |

Cov ntaub ntawv tseem ceeb rau hluav taws xob insulating cov ntaub ntawv, cov khoom siv lim, tiv thaiv corrosion, ya raws-pov thawj, tshav kub-insulating, suab-insulating, shock-absorbing cov ntaub ntawv, reinforcing cov ntaub ntawv thiab lwm yam ntaub ntawv, thiab yog dav siv nyob rau hauv textile phab ntsa mesh daim ntaub, sib tsoo log reinforcement Mesh, fireproof ntaub, lim ntaub thiab lwm yam ntaub ntawv. |

Feature |

• Zoo ntub-tawm hauv resins |

KEV UA HAUJ LWM

Haum rau kev siv zog ntxiv aluminium sulfate tsawg alkalinity cement, cov khoom lag luam yog raws li lub zog muaj zog thiab tsim kom muaj peev xwm tsim tau zoo rau GRC phab ntsa thiab lwm yam khoom siv hauv tsev, engineering engineering thiab infrastructure Cheebtsam.

TECHNICAL PARAMETERS

Linear Density (%) |

Cov dej noo (%) |

Qhov Loj (%) |

Kev nruj (mm) |

ISO 1889 Kev Tswj Xyuas |

ISO 3344 Kev Tswj Xyuas |

ISO 1887 Cov |

TS EN ISO 3375 |

± 4 |

≤ 0.10 |

0.50 ± 0.15 |

110 ± 20 |

IDENTIFICATION

Piv txwv |

E6R12-2400-512 |

Hom iav |

E6 |

Sib dhos Roving |

R |

Filament Txoj kab uas hla μm |

12 |

Linear Density, tex |

2400, 4800 Nws |

Loj Code |

512 |

TXOJ CAI TSHIAB

-

ZBREHON AR fiber ntau iav Roving yog tshwj xeeb tsim rau filament winding thiab pultrusion txheej txheem, tau tshaj epoxy resins, nrog curing tus neeg sawv cev ntawm acid angydride los yog amine.Cov khoom tiav tuaj yeem ua tau raws li qhov kev thov siab bursting, haum rau cov kav dej siab thiab cov thawv ntim siabDab tsi yog peb fiberglass roving khoom feature & zooZoo chopped kev ua tau zoo, zoo tis, anti-static thiab zoo flowability nyob rau hauv pwm xovxwm;Sib txawv acetone daws ceev raws li kev thov sib txawv;Cov ntaub ntawv sib xyaw yog cov neeg kho tshuab muaj zog, ua haujlwm zoo heev;Yooj yim ntub tawm, hluav taws xob (cov rwb thaiv tsev) kev ua tau zoo yog muaj zog.

ZBREHON AR fiber ntau iav Roving yog tshwj xeeb tsim rau filament winding thiab pultrusion txheej txheem, tau tshaj epoxy resins, nrog curing tus neeg sawv cev ntawm acid angydride los yog amine.Cov khoom tiav tuaj yeem ua tau raws li qhov kev thov siab bursting, haum rau cov kav dej siab thiab cov thawv ntim siabDab tsi yog peb fiberglass roving khoom feature & zooZoo chopped kev ua tau zoo, zoo tis, anti-static thiab zoo flowability nyob rau hauv pwm xovxwm;Sib txawv acetone daws ceev raws li kev thov sib txawv;Cov ntaub ntawv sib xyaw yog cov neeg kho tshuab muaj zog, ua haujlwm zoo heev;Yooj yim ntub tawm, hluav taws xob (cov rwb thaiv tsev) kev ua tau zoo yog muaj zog. -

ZBREHON AR-Glass fiber ntau yog tsim los ntawm ntau hom rau ntau lub hom phiaj. Chopped bundled fiber yog ib qho ntawm cov ntaub ntawv AR-Glass yog siv thaum lub pob zeb ntxiv. Qhov ntev ntawm cov fibers, qhov ntau lawv yuav tiv thaiv tsis ua hauj lwm. Lwm daim ntawv no hom fiberglass yuav siv sij hawm thaum reinforcing pob zeb yog roving. Qhov no yog ib qho txuas txuas ntxiv ntawm fiber ntau thiab feem ntau siv nrog lwm cov tshuab. Nws tau txiav thiab sib tov rau hauv slurry thaum lub sij hawm ua vaj tse. Thaum kawg, scrim yog ib daim ntaub woven ua los ntawm roving. Cov ntaub woven no kuj siv rau hauv cov pob zeb sib tov rau kev txhawb nqa.

-

ZBREHON AR-Glass fiber ntau Raws li cov ntsiab lus ntawm ZrO2 hauv iav cov khoom, cov khoom tau muab faib ua ob hom: L (tsis tshua muaj qhov yuam kev) thiab H (siab Hao). Cov ntsiab lus ntawm ZrO2 nyob rau hauv L iav Cheebtsam yog ntau dua los yog sib npaug rau 14.0% thiab cov nyiaj ua ke ntawm ZrOz thiab TiOz yog ntau dua los yog sib npaug rau 19.2% (saib 4.1 thiab 5.2, 4.1 thiab 5.1 ntawm 2002 version). - Hloov lub zog tawg kom tsis pub tsawg dua 0.26N / tex (saib 5.5, 5.5 hauv 2002 tsab); -- Cov ntsiab lus combustible muab faib ua Class C thiab Class W, nrog rau chav kawm C tsis tsawg dua 1.2% thiab Class W tsis tsawg dua 0.8%.

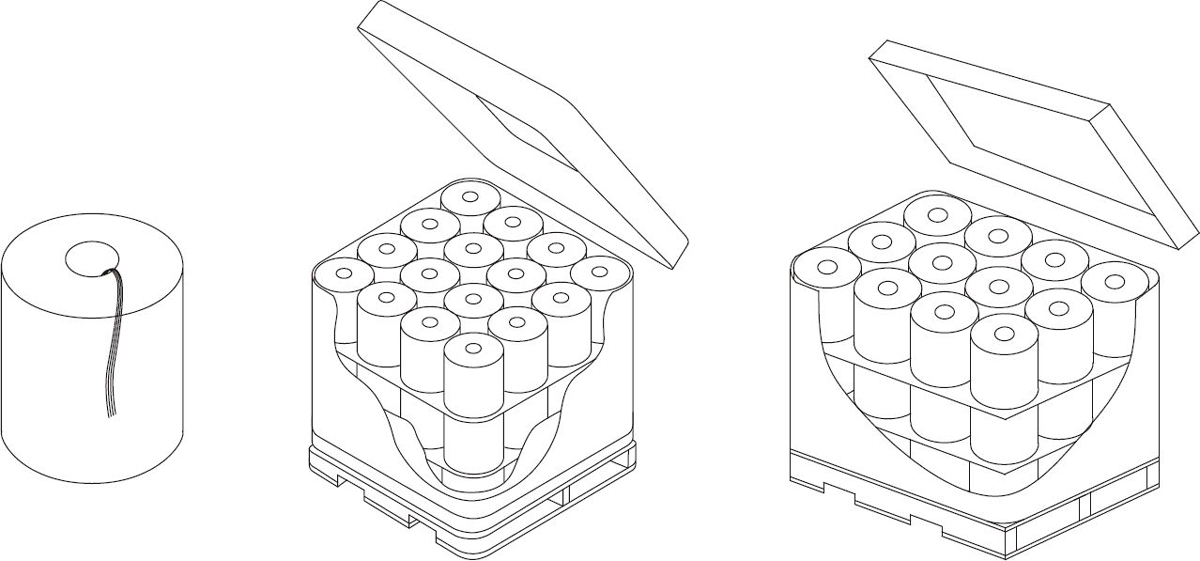

Ntim

Pob qhov siab mm (hauv) |

260 (10.2 hli) |

260 (10.2 hli) |

||

Pob hauv txoj kab uas hla mm (hauv) |

100 (3.9) |

100 (3.9) |

||

Pob sab nraud txoj kab uas hla mm (hauv) |

270 (10.6 hli) |

310 (12.2 hli.) |

||

Pob qhov hnyav kg (lb) |

17 (37.5) thiab |

23 (50.7) Nws. |

||

Cov txheej txheem |

3 |

4 |

3 |

4 |

Tus naj npawb ntawm doffs rau ib txheej |

16 |

12 |

||

Tus naj npawb ntawm doffs rau ib lub pallet |

48 |

64 |

36 |

48 |

Net nyhav ib pallet kg (lb) |

816 (1799) xyoo |

1088 (2399) hnub |

828 (1826) xyoo |

1104 (2434) hnub |

Pallet ntev mm (hauv) |

1120 (44.1) |

1270 (50) hnub |

||

Pallet dav mm (hauv) |

1120 (44.1) |

960 (37.8 hli) |

||

Pallet qhov siab (mm) |

940 (37) . |

1200 (47.2 hli) |

940 (37) . |

1200 (47.2 hli) |

Tsev

Tsev