Wind Power

Fiberglass is developing rapidly and is also widely used in the wind power industry. In particular, reinforced glass fiber products have developed rapidly in composite materials and can replace many traditional materials. ZBREHON's glass fiber products mainly include non-alkali yarn, medium-alkali yarn and glass fiber products. Different products are highly targeted in the market. They are usually used as reinforcing materials, electrical insulation materials and thermal insulation materials in composite materials for construction. Materials, transportation, electronic appliances, environmental protection wind power and other fields.

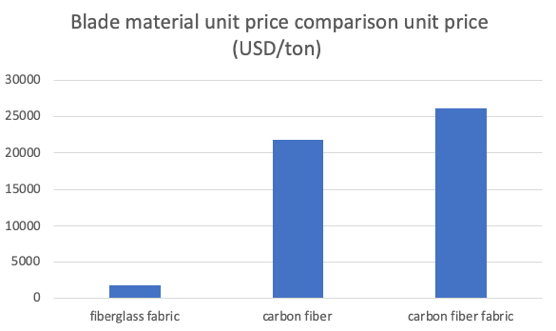

Glass fiber has a relatively high cost performance as a wind power reinforcement material. Due to the characteristics of light weight and high strength, ZBREHON machine glass fiber composite materials have great advantages in reducing carbon emissions such as lightweight products and comprehensive utilization of resources. Glass fiber has obvious advantages as a wind power reinforcement material, mainly because glass fiber not only has excellent performance, but also takes into account the economy. Studies have shown that the density of glass fiber is 67% lower than that of steel and 10% lower than that of aluminum alloy. When applied to wind power blades, it can greatly reduce weight, improve power generation efficiency, and reduce transportation costs. The tensile strength of glass fiber is 2 to 6 times higher than that of metal materials, and the tensile modulus is only slightly higher than that of aluminum alloy. At present, the tensile modulus of mainstream high-modulus glass fiber in the market reaches 89Gpa. In addition, the cost of reinforcing materials accounts for 21% of the total cost of wind power blades, and the cost of Zhangbei wind turbine accounts for a relatively large proportion. Therefore, economical efficiency should be considered in the selection of reinforcing materials. The mature industrial chain foundation of my country's glass fiber industry and the efforts to reduce costs over the years make glass fiber very cost-effective.