Fiberglass Chemical Composition: Unveiling the Elements for Optimal Performance

Introducing Zhongbao Ruiheng Technology Co., Ltd.'s Fiberglass with optimal chemical composition for diverse applications, Our Fiberglass is a versatile and high-performance material that finds extensive use in various industries. With a precise chemical composition, our product offers exceptional strength, durability, and resistance to heat, corrosion, and chemical reactions, Manufactured using state-of-the-art technology and strict quality control standards, our Fiberglass is composed of fine fibers made from a combination of glass and other additives. These fibers are woven together to form a strong and flexible material, Our Fiberglass is well-suited for insulation, construction, automotive, aerospace, and marine industries, among others. It can be used for thermal insulation, reinforcement in concrete structures, pipes, tanks, and panels, as well as electrical insulation, Benefits of our Fiberglass include excellent mechanical properties, light weight, low thermal conductivity, and high resistance to environmental conditions. Its chemical composition ensures long-lasting performance in demanding applications, At Zhongbao Ruiheng Technology Co., Ltd., we are dedicated to providing high-quality Fiberglass that meets international standards. Our commitment to customer satisfaction and continuous improvement allows us to deliver superior products for a range of industrial needs. Trust Zhongbao Ruiheng Technology Co., Ltd. for your Fiberglass requirements

- Wholesale Powder Fiberglass Chopped Strand Mat

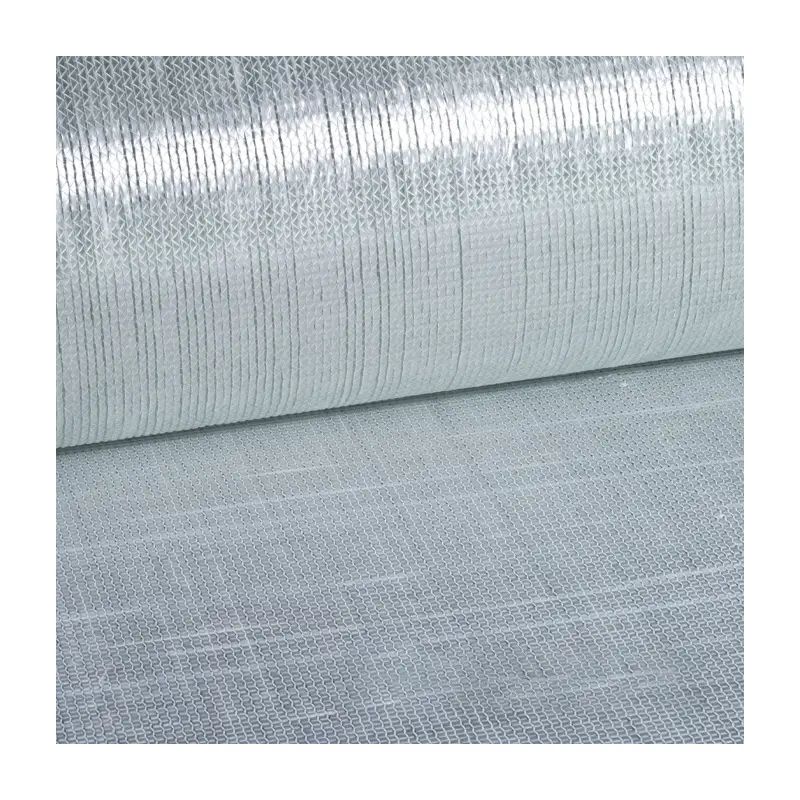

- Wholesale E-Glass Fibreglass Chop Strand Matts

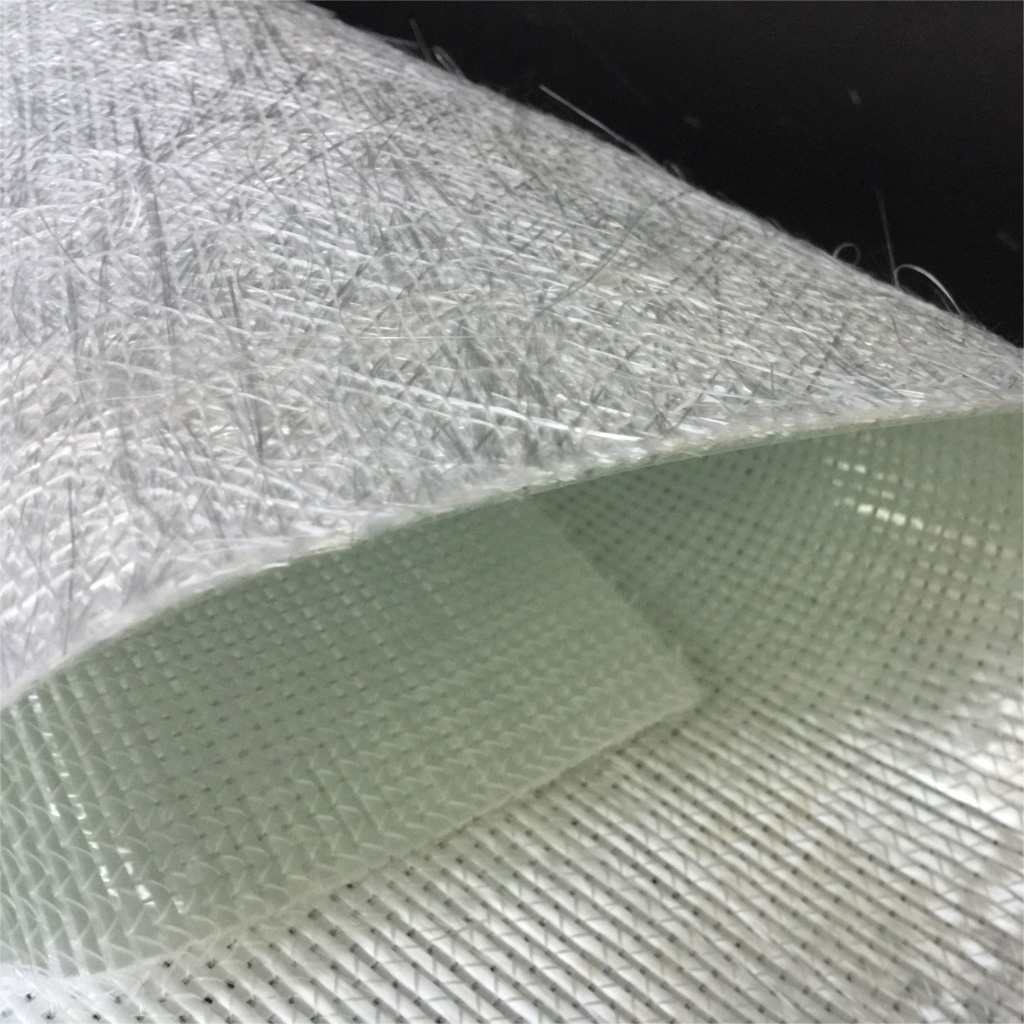

- China Thin Chopped Strand Fiberglass Mat Scrim

- China High Temperature Silica Fiberglass Cloth

- China Use Widely Fiberglass Chopped Strand Mat

- Wholesale Fibreglass Corrugated Roofing Sheets

- Wholesale Reinforced Fiberglass Roofing Tissue

- Wholesale Fiberglass Tissue Mat For Insulation

- Wholesale Eglass Fiberglass Chopped Strand Mat

- Wholesale Basalt Chopped Fiber For Asphalt Road