E-Glass Assembled Panel Roving

Video

Product Details

Product name |

E-Glass Assembled Panel Roving |

||

MOQ |

≥1000KG |

|

|

Characteristic |

1.Good cutting dispersion |

||

Technical Index

linear density(%) |

moisture content(%) |

combustible matter content(%) |

break strength(N/tex) |

ISO 1889 |

ISO 3344 |

ISO 1887 |

ISO 3375 |

±5 |

≤0.10 |

0.55±0.15 |

≥0.3 |

Specification

Product Code |

Fibre Type |

Linear Density(tex) |

Fibre Diameter(μm) |

Applicable resin |

Combustible content (%) |

ER-2400-836 |

E-Glass |

2400 |

12 |

UP, VE |

0.4-0.6 |

ER-4800-836 |

E-Glass |

4800 |

12 |

UP, VE |

0.4-0.6 |

Application

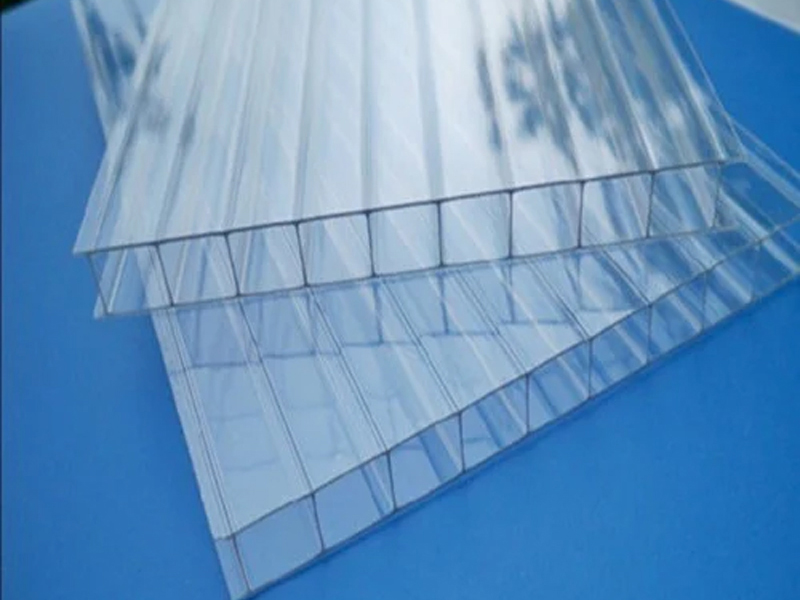

It is used to produce glass fiber transparent board.

Contact us, we will send you product information quotations and lightweight solutions!Advantage

ZBREHON E-Glass Assembled Panel Roving is formulated with silane-enhanced sizing, which has the advantages of excellent cutability, stiffness, dispersibility, fast soaking, high strength and good transparency of the sheet.

In the molding process, the resin mixed is uniformly deposited onto the moving film at the constantspeed. The thickness of the resin is controlled by the draw-knife. The fiberglass roving is chopped, metered and uniformly distributed onto the resin. After chopping, the top film is laid-on forming a sandwichstructure. The wet assembly travels through the curing oven before de-molding. lt is cut into different sizepanel finally. The finished product has light weight, high strength, high impact resistance and excellent transparency.

Product have advantage: Good choppability; Excellent dispersion; Low static; High strength property offinished panels; Fast wet out, high translucendyproperty; Mainly used for transparentpanels and daylighting panels.

Packing & Shipment

Each rolls is approximately 18KG, 48/64 rolls a pallet, 48 rolls are 3 floors and 64 rolls are 4 floors. The 20-foot container holds about 22 tons.

description1