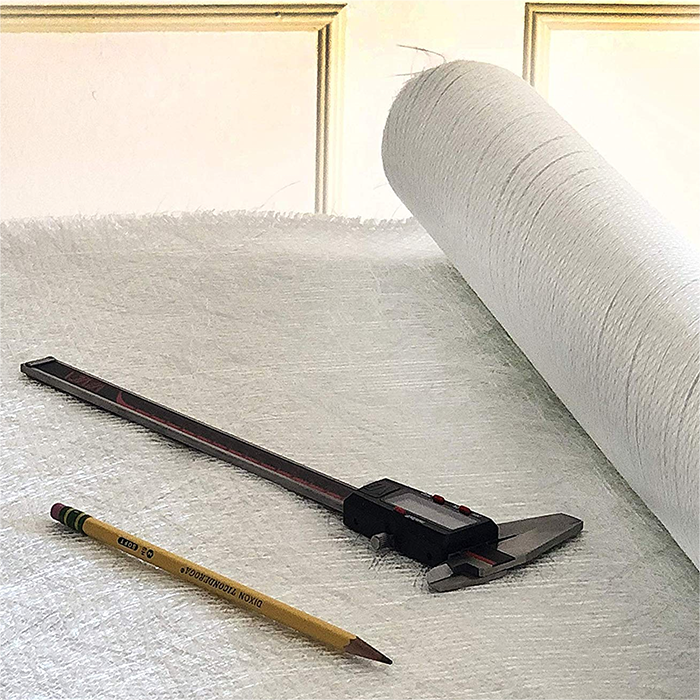

450g stitched biaxial fiberglass fabric

Product Details

Product name |

450g stitched biaxial fiberglass fabric |

||

MOQ |

≥1000KG |

|

|

Application |

Biaxial fiberglass fabric is wildly used in aerospace field, automobile industry, wind energy, construction and so on |

||

Feature |

1. Strength and stability |

||

Technical Index

Standing Temperature |

Weight |

Width |

-70-1000℃ |

825g/m² |

1.02 or 1.27M |

Precautions

Note when using stitched biaxial fiberglass fabric:

1. Wearing appropriate personal protective equipment such as gloves, safety goggles, and a dust mask to minimize skin contact and inhalation of fibers.

2. Working in a well-ventilated area and using dust extraction systems can help reduce the risk of airborne particles.

3. Proper training on handling and cutting the fabric is crucial to ensure safe practices and minimize the potential for accidents.

4. Regularly cleaning work surfaces and disposing of waste materials in accordance with regulations is also important to maintain a safe working environment.

Show Results

LABELLING

• Each roll bears a label stating product description, product nominal weight (g/m2), product roll width, product code, net weight, production number and shift number, roll number.

• Mat rolls are supplied in a protective polythene bag in a one-piece carton box. These are placed vertically on wooden pallets and shrink-wrapped for stability and protection.

description1