Fiberglass Powder Chopped Strand Mat

Product Details

Product name |

Fiberglass powder chopped strand mat |

||

MOQ |

≥1000KG |

|

|

Application |

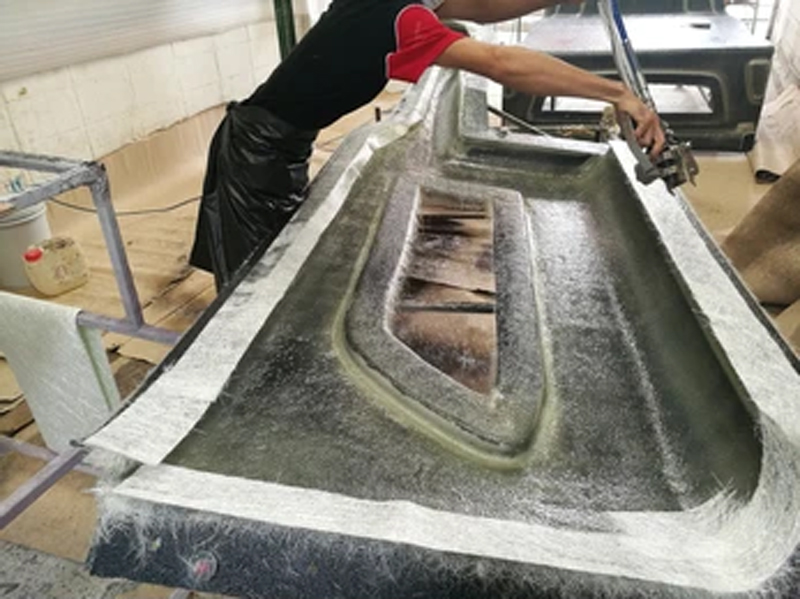

Glass fiber powder chopped strand mat is used as reinforcement in the production of composite materials such as boat building, automotive parts, wind turbine blades 、Hull, bathtub, cooling tower, anti-corrosion materials, vehicle components and various construction applications. |

||

Feature |

• The surface of the laminate is smooth and has good light transmission |

||

PERFORMANCE ATTRIBUTES

-

GOOD MECHANICAL PROPERTIES

-

FAST SOAKING SPEED AND GOOD MOLD COVERAGE

-

HIGH WET STRENGTH RETENTION

-

GOOD DISPERSION AND UNIFORMITY

Product code |

Glass type |

Unite weight (g/m2) |

Width(mm) |

Roll weight (kg) |

Moisture (%) |

Binder content (%) |

Binder Type. |

EMC100 |

E/C Glass. |

100+/-20 |

1040-1270 |

30- 50. |

<0.2-0.3. |

2-6. |

PowderEmulsion |

EMC150 |

E/C Glass. |

150+/-20 |

1040-1270 |

30-50. |

<0.2-0.3. |

2-6. |

PowderEmulsion |

EMC200 |

E/C Glass. |

200+/-20. |

1040-1270 |

30-50. |

<0.2-0.3. |

2-6. |

PowderEmulsion |

EMC300 |

E/C Glass. |

300+/-20 |

1040-1270 |

30-50. |

<0.2-0.3. |

2-6. |

Powder/Emulsion |

EMC450 |

E/C Glass. |

450+/-20. |

1040-1270 |

30-50. |

<0.2-0.3. |

2-6. |

Powder/Emulsion |

EMC600 |

E/C Glass. |

600+/-20. |

1040-1270 |

30-50. |

<0.2-0.3. |

2-6. |

Powder Emulsion |

EMC 900. |

E/C Glass. |

900+/-20 |

1040- 1270 |

30-50. |

<0.2-0.3. |

2-6. |

Powder/Emulsionl |