Discover High-Quality Core Material for Fiberglass

Introducing ZHONGBAO RUIHENG TECHNOLOGY CO., LTD., a leading provider of high-quality core materials for fiberglass manufacturing. With our cutting-edge technology and commitment to excellence, we offer a wide range of innovative products to meet the diverse needs of our customers, Our core materials play a fundamental role in reinforcing and enhancing the strength, durability, and insulation properties of fiberglass composites. We specialize in producing core materials made from advanced materials such as foam, honeycomb, and balsa wood, providing exceptional strength-to-weight ratio and thermal insulation properties, At ZHONGBAO RUIHENG TECHNOLOGY CO., LTD., we prioritize quality and strive for continuous improvement in our manufacturing processes. Our core materials are meticulously manufactured under strict quality control measures to ensure exceptional performance and reliability. We also adhere to international standards and guidelines, ensuring the compatibility of our products with various fiberglass manufacturing techniques, Our team of experienced professionals is dedicated to providing personalized solutions to our customers. We work closely with them to understand their specific requirements and offer tailored core material solutions to optimize production efficiency and product performance, Choose ZHONGBAO RUIHENG TECHNOLOGY CO., LTD. for top-quality core materials that will elevate the performance and durability of your fiberglass products. Contact us today to explore our extensive range of core materials and discuss how we can support your manufacturing needs

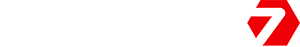

- Chopped Fiberglass Mat

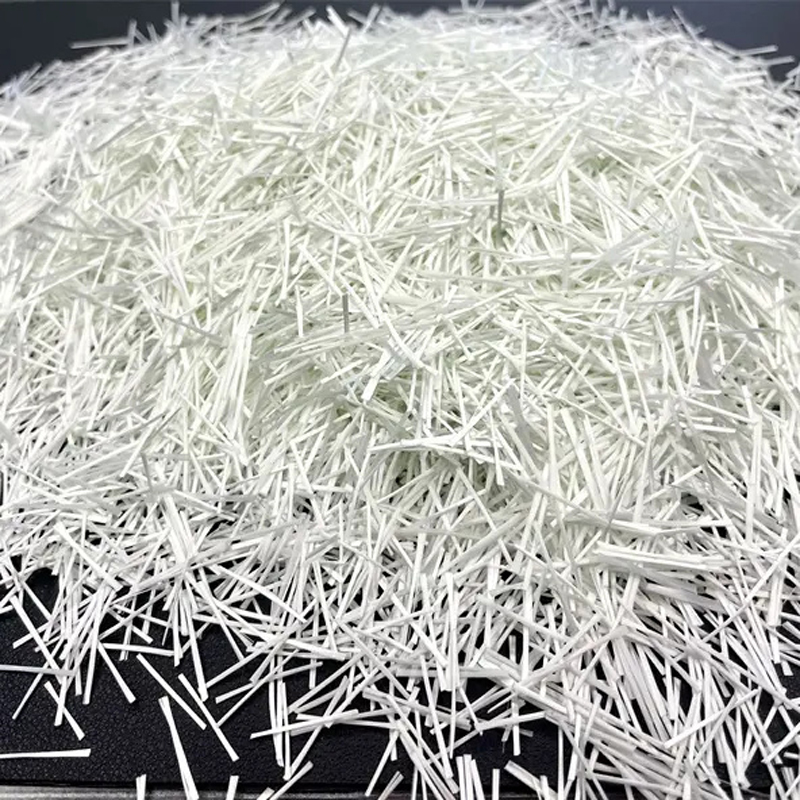

- Wholesale Fiberglas Resin Suppliers

- China Black Fiberglass Insulation Supplier

- China Strand Fiberglass Suppliers

- China Basalt Fiber Bar Suppliers

- Wholesale Power Chopped Strand Mat Supplier

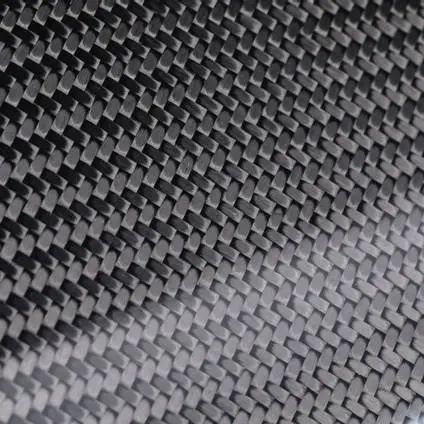

- Carbon Fiber Fabric Sheets Suppliers

- Wholesale Fiberglass Nonwoven

- Wholesale Fiber Glass Sheet Factories

- 2x2 Twill Carbon Fiber Suppliers