E-Glass Assembled Roving Rau Txau

Video

Khoom Paub meej

Khoom npe |

E-Glass Assembled Roving Rau Txau |

||

MOQ |

≥1000KG |

||

Daim ntawv thov |

Feem ntau yog siv los ua GRP nkoj, khoom siv tu cev, cia tank thiab Hobas kav, thiab lwm yam |

||

Feature |

1. Kev ua haujlwm zoo |

||

KEV UA HAUJ LWM

-

Kev ua tau zoo txiav

-

ZOO TSHAJ PLAWS Moulding

-

ZOO TSHAJ PLAWS

-

Compatible nrog ntau yam resins

Specifications

Yam khoom |

Specification |

Txuj No. |

|

Linear density (tex) |

2400 ± 120 |

3000 ± 150 |

TS EN ISO 1889-1997 |

Poob ntawm ignition (%) |

1.00 ± 0.15 |

1.00 ± 0.15 |

ISO 1887-1995 Kev Tswj Xyuas Zoo |

Cov dej noo (%) |

≤0.1 |

≤0.1 |

TS EN ISO 3344-1997 |

Kev nruj (mm) |

135 ± 15 |

135 ± 15 |

TS EN ISO 3375-1997 |

Technical Parameter

Khoom code |

Hom Fiber |

Linear Density (tex) |

Ib txoj kab uas hla (μm) |

Siv tau resin |

Cov ntsiab lus combustible (%) |

ES-2400-618 |

E-iav |

2400 |

13 |

UA, VE |

1.2-1.6 |

ES-4800-618 |

E-iav |

4800 ib |

13 |

UA, VE |

1.2-1.6 |

APPLICATION

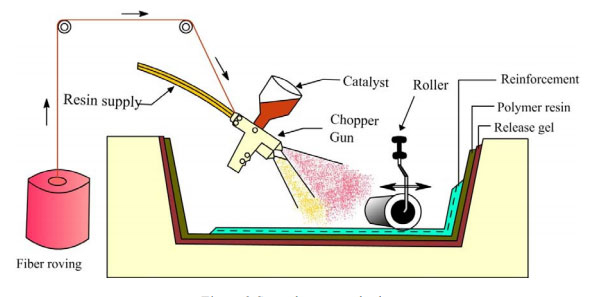

Cov khoom no yog dav hlau roving, uas yog dav siv nyob rau hauv lub teb ntawm manufacturing ships, yachts, sanitary ware, da dej pas dej ua ke thiab nws pib qhov chaw vim nws cov khoom zoo heev ntawm cov khoom yooj yim. Txhim kho corrosion kuj, alkali tsis kam thiab durability ntawm cov khoom rau koj. Cov kav dej kuj tseem tuaj yeem tsim los ntawm cov txheej txheem centrifugal casting.

Tiv tauj peb, peb yuav xa koj cov ntaub ntawv hais txog cov khoom thiab cov kev daws teeb meem!Qhov zoo

Txheej Txheej Txheej Txheej

Tsev

Tsev