E-Glass e Kopantsoeng Roving Bakeng sa Spray Up

Video

Lintlha tsa Sehlahisoa

Lebitso la sehlahisoa |

E-Glass e Kopantsoeng Roving Bakeng sa Spray Up |

||

MOQ |

≥1000KG |

||

Kopo |

haholo-holo e sebelisetsoang ho hlahisa likepe tsa GRP, thepa ea bohloeki, litanka tsa polokelo le liphaephe tsa Hobas, joalo-joalo. |

||

Sebopeho |

1. Ts'ebetso e ntle ea ho itšeha |

||

LIEKETSENG TŠEBELETSO

-

MOSEBETSI E MOKHOA

-

MOSEBETSI OA MOKHATLO OA MOKHOPO

-

KHASANE MOSEBETSI

-

E BONAHALA LE LITŠOANTŠISO TSA MEFUTA

Litlhaloso

Ntho |

Tlhaloso |

Standard No. |

|

Boima ba linear (tex) |

2400±120 |

3000±150 |

ISO 1889 - 1997 |

Tahlehelo nakong ea ho hotetsa ( %) |

1.00±0.15 |

1.00±0.15 |

ISO 1887 - 1995 |

Mongobo ( %) |

≤0.1 |

≤0.1 |

ISO 3344 - 1997 |

Ho satalla (mm) |

135±15 |

135±15 |

ISO 3375 - 1997 |

Tekheniki Parameter

Khoutu ea sehlahisoa |

Mofuta oa Fiber |

Linear Density(tex) |

Bophara ba khoele e le 'ngoe (μm) |

Resin e sebetsang |

Litaba tse tukang (%) |

ER-2400-618 |

Khalase ea E |

2400 |

13 |

PHAHAMA, VE |

1.2-1.6 |

ER-4800-618 |

Khalase ea E |

4800 |

13 |

PHAHAMA, VE |

1.2-1.6 |

KOPO

Sehlahisoa sena ke jet roving, e sebelisoang haholo masimong a ho etsa likepe, li-yachts, thepa ea bohloeki, matamo a ho sesa le likarolo tsa likoloi ka lebaka la thepa ea eona e babatsehang ea thepa e bonolo. Ntlafatsa khanyetso ea kutu, khanyetso ea alkali le ho tšoarella ha sehlahisoa molemong oa hau. Liphaephe li ka boela tsa etsoa ka mokhoa oa ho lahla centrifugal.

Ikopanye le rona, re tla u romella mantsoe a qotsitsoeng a tlhahisoleseling le litharollo tse bobebe!Molemo

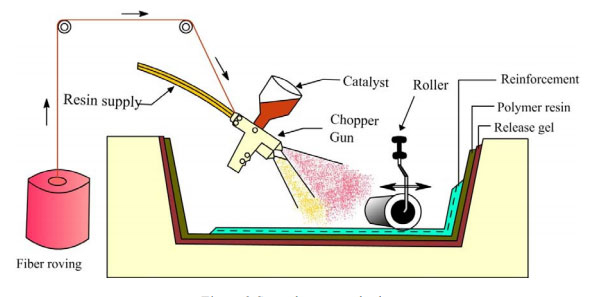

Mokhoa oa ho fafatsa oa ho beha

Lehae

Lehae