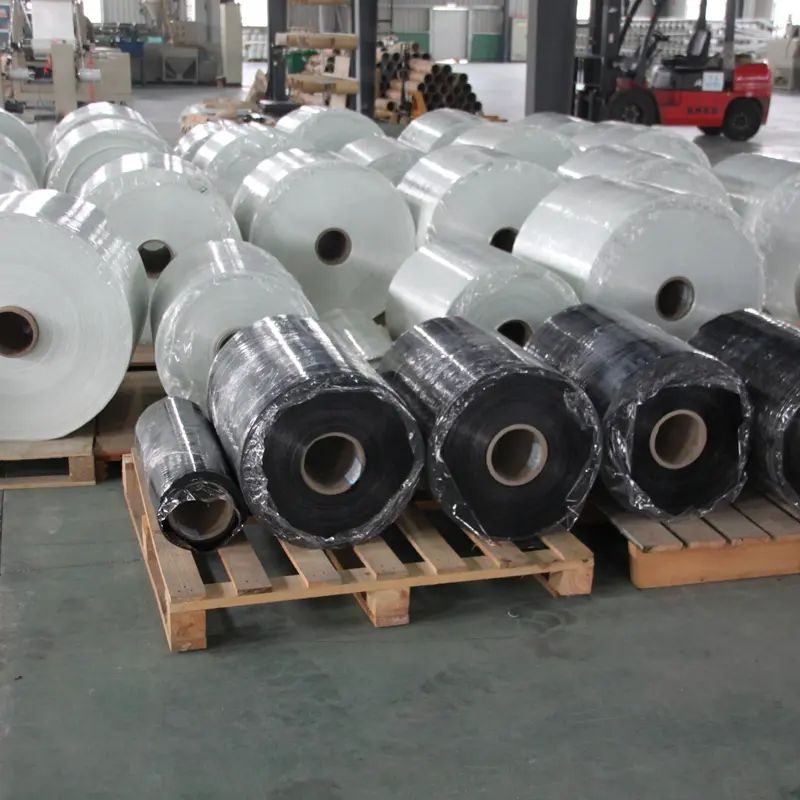

E-Glass Assembled Roving For Spray Up

Video

Product Details

Product name |

E-Glass Assembled Roving For Spray Up |

||

MOQ |

≥1000KG |

|

|

Application |

mainly used for producing GRP ships,sanitary ware,storage tanks and Hobas pipes,etc |

||

Feature |

1. Good cutting performance |

||

PERFORMANCE ATTRIBUTES

-

GOOD CUTTING PERFORMANCE

-

EXCELLENT MOLDING PERFORMANCE

-

GOOD DISPERSION PERFORMANCE

-

COMPATIBLE WITH VARIOUS RESINS

Specifications

Item |

Specification |

Standard No. |

|

Linear density (tex) |

2400±120 |

3000±150 |

ISO 1889 - 1997 |

Loss on ignition ( % ) |

1.00±0.15 |

1.00±0.15 |

ISO 1887 - 1995 |

Moisture content ( % ) |

≤0.1 |

≤0.1 |

ISO 3344 - 1997 |

Stiffness (mm) |

135±15 |

135±15 |

ISO 3375 - 1997 |

Technical Parameter

Product code |

Fiber Type |

Linear Density(tex) |

Single filament diameter (μm) |

Applicable resin |

Combustible content (%) |

ER-2400-618 |

E-Glass |

2400 |

13 |

UP, VE |

1.2-1.6 |

ER-4800-618 |

E-Glass |

4800 |

13 |

UP, VE |

1.2-1.6 |

APPLICATION

This product is a jet roving, which is widely used in the fields of manufacturing ships, yachts, sanitary ware, swimming pools and auto parts due to its excellent property of easy properties. Improve the corrosion resistance, alkali resistance and durability of the product for you. Pipes can also be manufactured by the centrifugal casting process.

Contact us, we will send you product information quotations and lightweight solutions!Advantage

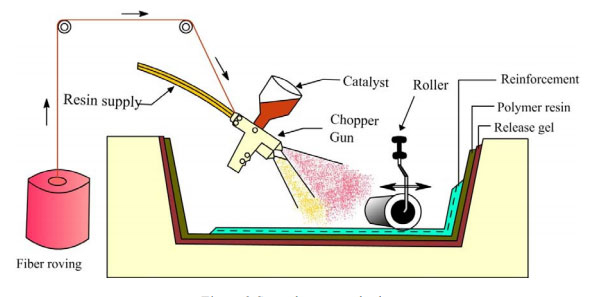

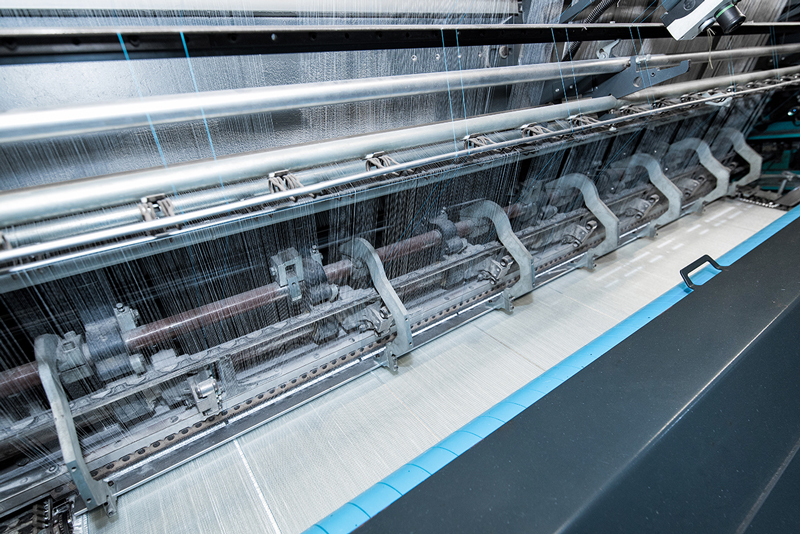

Spray Lay-Up Process